This American bred German born beast is our 2001 Corvette C5R!

Purchased new in Germany and Autobahn driven her first year this machine underwent significant retooling back in the states with only 15,000 miles on the ticker.

|

|

Shown here in track wheels form sporting HRE 3-Piece Forged Aluminum Racing Wheels (18x10 fronts and 19x10 rears) wrapped in Pirelli P Zero Rosso Asimmetrico N4 Tires.

|

|

|

|

The day I took possession was also our first snow in Germany. By the time I got back to Sembach AFB there was between 2.5 and 3 inches

on the ground. Getting a brand new, lightweight, big tire, rear wheel drive car up that long hill was a harrowing experience!

|

|

|

|

|

|

|

Parked outside my work center on Ramstein AFB Germany.

|

|

|

|

Hanging out in a small German village.

|

|

|

|

Getting back to the U.S. was a matter of driving to Belgium (shown here) and loading her into a cargo container for shipping. Once stateside I

picked her up in Baltimore Maryland and drove back to Cincinnati Ohio.

|

|

|

|

Living with her older sister back home in Dallas just after a second round of dyno tuning!

|

|

|

|

|

|

|

The Afterlife! Fast-forward to late 2015.

Some detuning is in order so as you can see here the original LS1 is devoid of its Lingenfelter CNC Ported Z06 Racing Heads, ASA Racing

Camshaft, Timing Set, Oil Pump and just about everything else save for the block, crank, rods and pistons.

|

|

|

|

After a little gasket surface cleanup the camshaft, oil pump and timing set are installed followed by the timing cover.

|

|

|

|

Next up was a fresh set of GM head gaskets, the original 4241 casting heads—which had been sitting in the corner of the shop for more than ten

years—and new torque to yield bolts. After the five phase torque sequence (22 ft. lb., 90 degrees, 90 degrees, 50 degrees & 22 ft. lb. top row) the

valley cover and gasket was torqued in place followed by the two knock sensors and wiring harness.

|

|

|

|

Here the pushrods, rocker girdles and rocker arms were reinstalled followed by the valve covers and headers.

|

|

|

|

Before the A/C belt could be installed its upper idler pulley had to be replaced. This is a difficult belt to access after its all together so pay me now is

better than later! Then the accessory brackets, power steering pump, alternator, belt and hydraulic control unit was installed. Finally, the

radiator, fans, lower air dam, hoses, lines and upper radiator shroud was installed to button up the front of the motor.

|

|

|

|

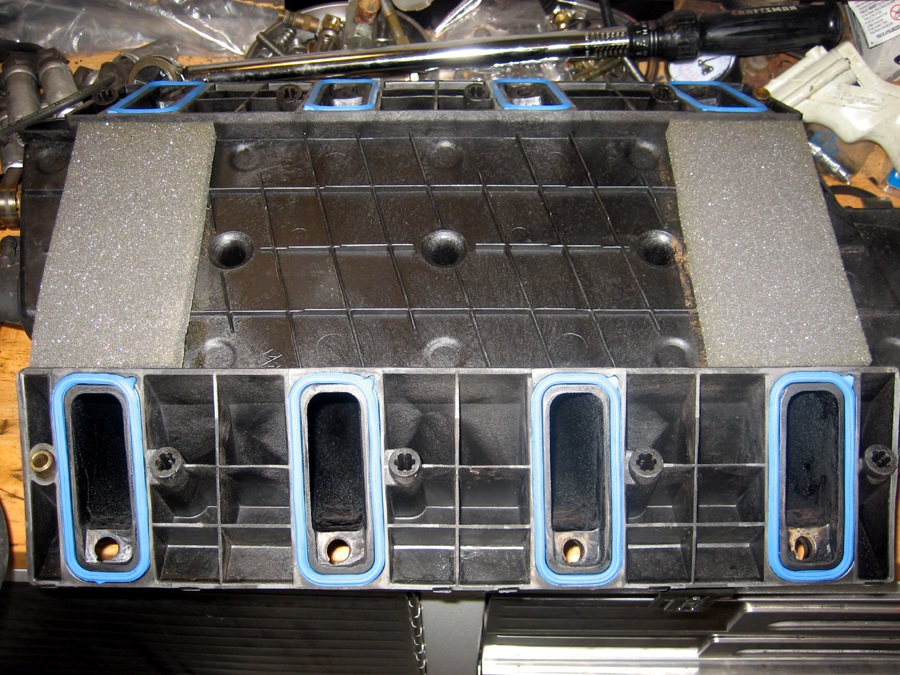

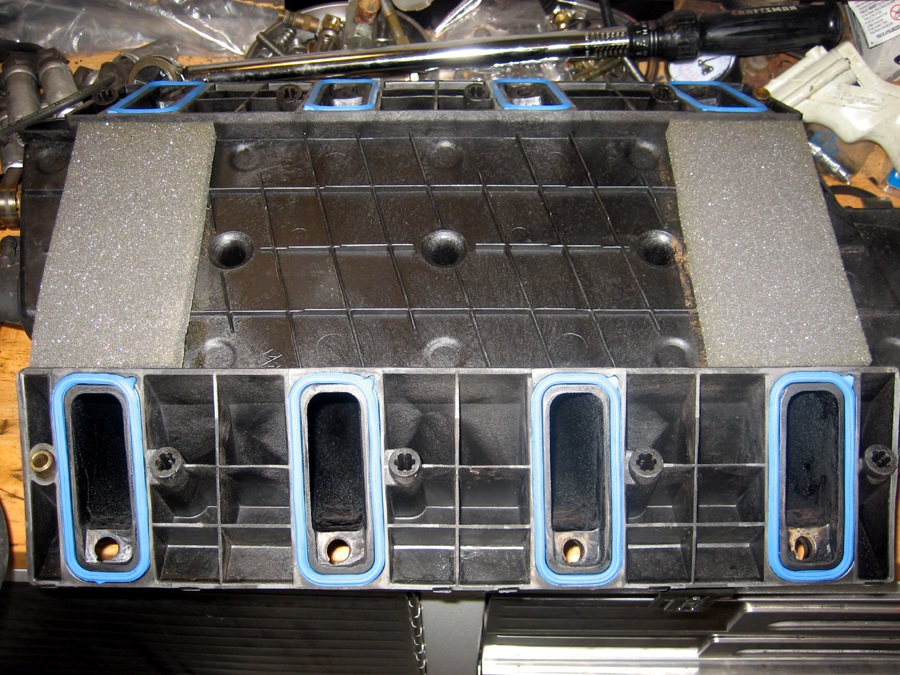

Next the air and fuel delivery pieces were installed, beginning with preparing and installing new Fel-Pro gaskets and foam pads on our composite

intake manifold followed by the Z06 Fuel Injectors (28 lb/hr) which replaced the larger Magnuson Supercharger Kit Injectors (42 lb/hr) in our fuel

rails. The final shot shows these components installed along with coil packs and wire harnesses.

|

|

|

|

With the engine all buttoned up work on the ram air induction system can begin. This is a bottom view of the cold air intake under the nose of

the car.

|

|

|

|

The VariRam ram air system is back in place along with a clean K&N air filter. Next up was the exhaust system which included new aluminum

collector gaskets and bolts. Note the two forward mufflers. There are also two SS GHL units out back which this photo doesn’t show. Still too

loud but she flows well!

|

|

|

|

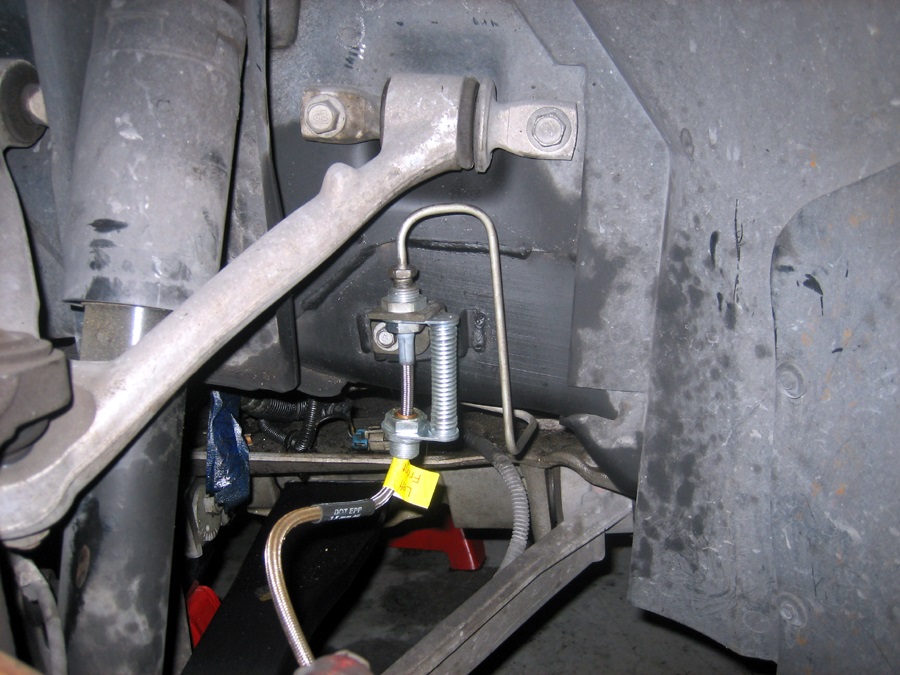

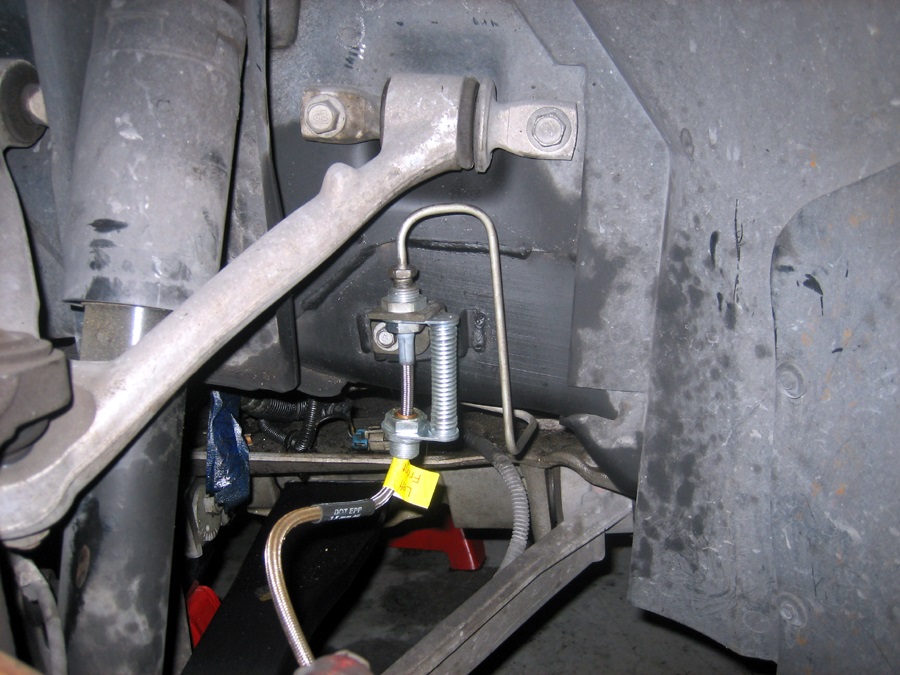

Earl’s Plumbing Teflon Lined SS Brake lines were installed on all four corners. The fronts have their patented spring loaded strain relief which

earned them DOT approval early in the game. After which the entire system was flushed down with new fluid and air bled.

|

|

|

|

Finally, back on rolling stock and ready to hit the streets once again!

These wheels are based on the Z-06 rollers but are chrome and the

absolute widest size I could tuck inside the factory wells. The staggered fronts measured 19x10 and the massive rears came in at 20x11.

|

|

|

|