Taken in trade for my 1991 454SS, this 2000 Corvette Delco/Mongoose 400 SS Edition was certainly someone’s pride and joy. There were easily more aftermarket add on parts than the entire car was worth. One of my favorites are these 3-Piece Forged BBS (German) Wheels wrapped in new rubber estimated north of five grand.

The Fives (today)!

The first couple days were spent sorting out all the little things typical of an eighty thousand mile Corvette, like rebuilding both front seat tracks, replacing the passenger window regulator, repairing the broken cup holder door and console lid, fixing some grounds and clearing OBD codes.

Still running down grounds that have corroded or just lost their conductivity over the years. A very common problem with the C5. Here are the points you want to disassemble, wire brush, coat in dielectric grease and reassemble tightly. I prefer eliminating these connector boxes, altogether. Just solder all the wires into a bundle and crimp them into a spade connector. Then when bolting it back onto the clean frame, place SS star washer on bottom and SS flat washer on top.

Altitude is Attitude! So out came the front spring snubbers and longer, hardened bolts a new bushings went into the rear. When I first saw the car it appeared to lean somewhat to the right but it was difficult to tell on an unimproved surface. Once up on the lift it was obvious the factory spring bushing on that side had disintegrated.

Keeping the rear brakes cool on the track requires some bodywork back home. After ordering the AC Delco (OEM) Z06 brake scoops and interior ducts the rocker panels and inner fender wells were carefully marked and cut. With installation complete everything appears to be OEM once again.

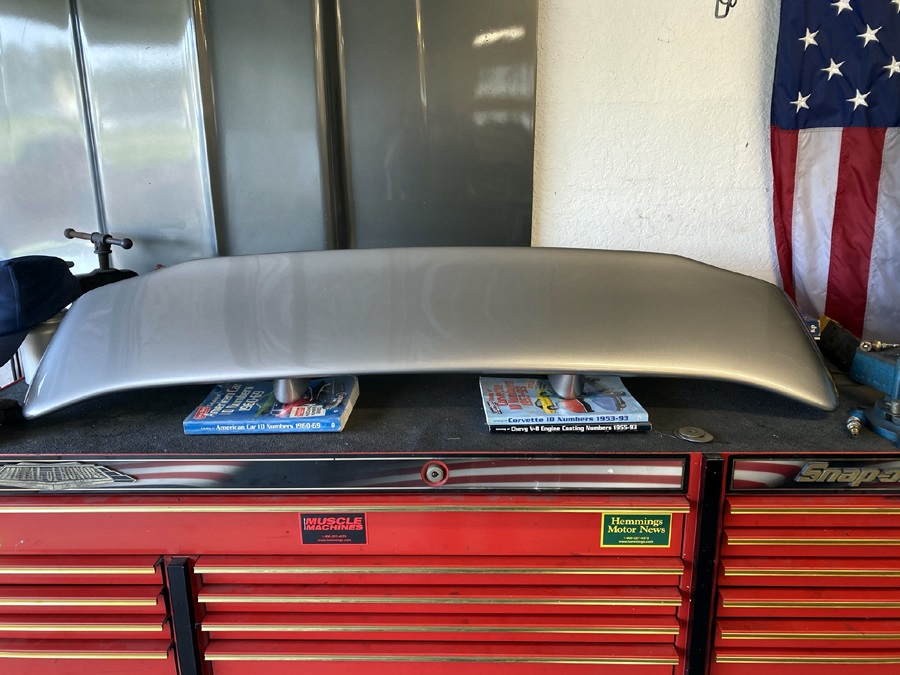

Retaining the original body lines I opted for a factory appearing hood with a raised cowl to promote heat extraction and make room for what will eventually be a supercharger. Out back is a wing I found in a local wrecking yard (purchased the entire rear fascia from a bygone race car). The idea is to create a menacing appearance by lowering and lengthening its stature.

It took several hours to clean up and prep the dashboard and prep these burlwood overlays—time well spent!

As is typically the case for those inflicted by the hot rod virus, what started out as a simple upgrade—bolt-on or two—turned into a major project. The original plan was to drop a supercharger on it but current pricing ranged from $6,000 to $10,000 just in the parts (new). Ridiculous! The plan isn’t off, just delayed while shopping for the better deals.

In the meantime, however, I did opt for some bolt-ons to push the mill to the 450-490hp range in N/A trim. That foundation would help in the destruction of tires and provide a solid baseline for the aforementioned supercharger.

Closer inspection during teardown would reveal several performance upgrades such as a Z06 camshaft, Z06 intake, ported throttle body and ram air intake system.

The camshaft #’s are 0968 4 08 9231 which makes it a 2000, P/N 12560968, 198/209 Duration, 0.500/0.500 Lift, 115.5 LSA which is considered the best of the LS1 OEM camshafts. It’s also the hardest to find.

The intake casting #’s are 12573572 which translates to a late model factory LS6 (Z06) intake P/N 88894339.

Out with the old and in with the new! I chose a much more streetable camshaft for this one as apposed to the LSA Racing Cam I put in the 2000. This one is an off-the-shelf COMP Cams 54-444-11 XFI XE-R, Hydraulic Roller Cam with a 750-6,200 RPM Operating Range. With 0.581"/0.592" Valve Lift at 224/230 Duration at .050" and 114 Degree Lobe Separation Angle tuning wasn’t a problem and it doesn’t require near the fuel at idle.

Of course the swap required new valve springs, retainers and poly locks along with a custom tool for on head-on car installation.

Left over from a previous project were a pair of GM Factory Z06 Heads (243 Castings) that Lingenfelter Performance had fully CNC’d, Decked .040” for a 61cc CC and sold through GM Performance as Showroom Stock & World Challenge Racing Heads, P/N 25534321. These flow 256 CFM Intake & 194 CFM Exhaust at .500” Lift and 260 CFM Intake & 208 CFM Exhaust at .600” Lift

Certainly the most painfully expensive intake I’ve ever purchased is the F.A.S.T. LSXr 102mm unit shown here. The intake must be disassembled to drill out the IAS mount location of choice. In doing so I came to realize their poor quality control as the gasket on the other end of this lower shell had been installed incorrectly and now has a permanently kinked spot requiring silicon sealer to function properly.

If you look closely at the fuel rails, they had to be machined to properly locate the intake tabs. This is where having your own machine shop saves the day.

As if a poor quality thousand dollar intake wasn’t painful enough, I quickly learned how hard—almost impossible—it is to get a 102mm Throttle Body to work with a pre-2000 Corvette. GM had changed computer designs and left 1997-2000 owners in the lurch. After some trial and error I finally had to return the $200 Throttle Bodies (plural) and pay over $700 for one modified to work with these inferior computers.

While buttoning up the bottom end a Romac Pro Series, SFI 18.1 Spec, 25% Underdrive dampener pully was added. I machined a pin alignment fixture from some cold roll bar stock to drill both crankshaft and pully for these 1/4" steel dowel pins. Slippage shouldn’t be an issue in N/A form but a supercharger may eventually force the pulley to spin.

Rounding out this, “simple bolt-on build,” is a full stainless steel exhaust starting with 1 7/8” Primary, Long Tube Headers connected to Off-Road X-and Mid-Pipes followed by a pair of SLP SS Cat-Back Mufflers. The trick exhaust tips are actually a full, one piece, cast aluminum manifold.

And finally, off to the Dyno!