Mid-Engine, IRS, 5-Speed, Composite Body Two-Seat Sport Car--what's not to love about that?

This is a case of GM executives inadvertently killing one brand to protect another as they feared the impact Pontiac would have on their hallowed Corvette.

Much like the 1964 Pontiac Banshee a.k.a. XP-833 project developed by Chief Engineer Elliot "Pete" Estes and then head of Pontiac, John De Lorean, the Fiero was denied its day and its design later developed into a Corvette (Banshee/C3; Fiero/C8).

The 1986 Fiero GT weighed in at an unheard of 2,700 lbs. and came standard with the 140hp, 2.8-liter V-6 and dual exhausts, a Muncie-built Getrag five-speed manual transmission, staggered-width 15-inch diamond-spoke alloy wheels, four-wheel power disc brakes and could be had for a mere $12,999.

|

|

Don’t get me wrong, I love the Corvette (American Made); so in the near future this one will sport a GM LS4 Engine. In the meantime, I’m going to

enjoy the car as-is while knocking out a couple other projects. This bucket list item (compete in Holley’s LS Fest) will have to wait!

|

|

|

|

Aesthetics do have impact, so the missing center caps have been replaced along with the nose emblem (which was not easy to locate).

|

|

|

|

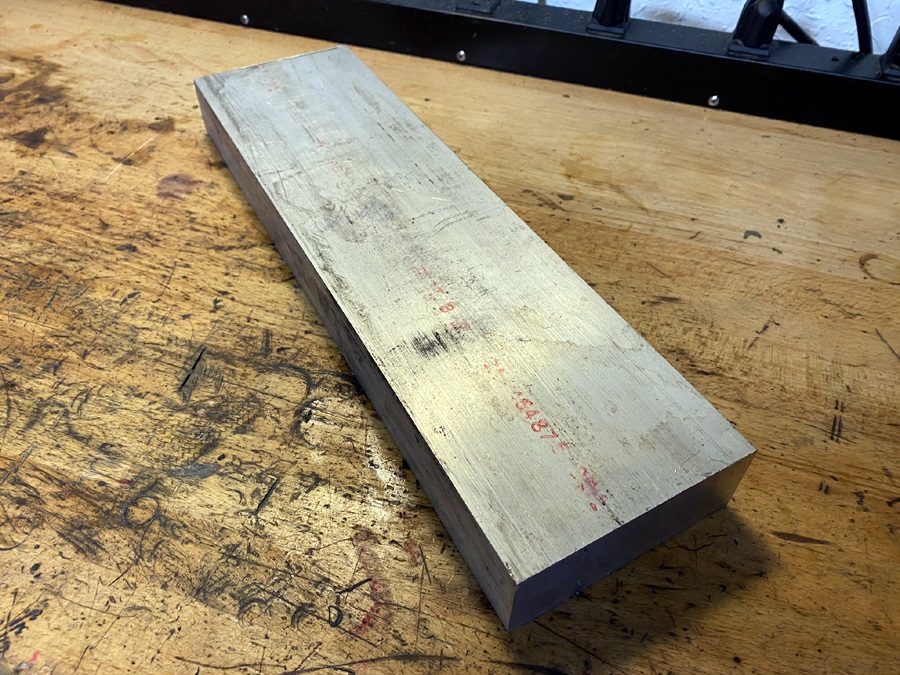

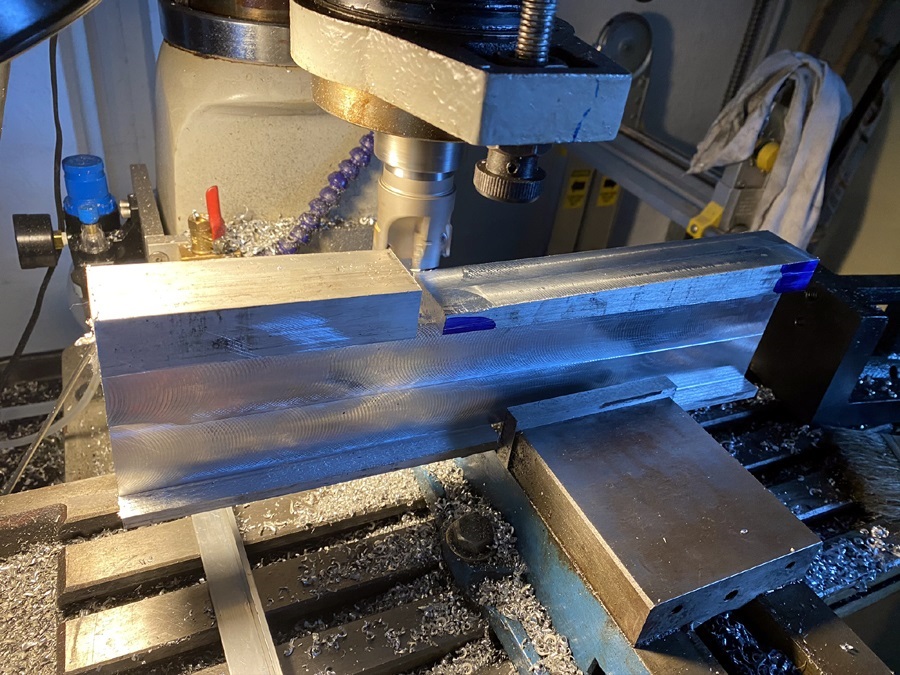

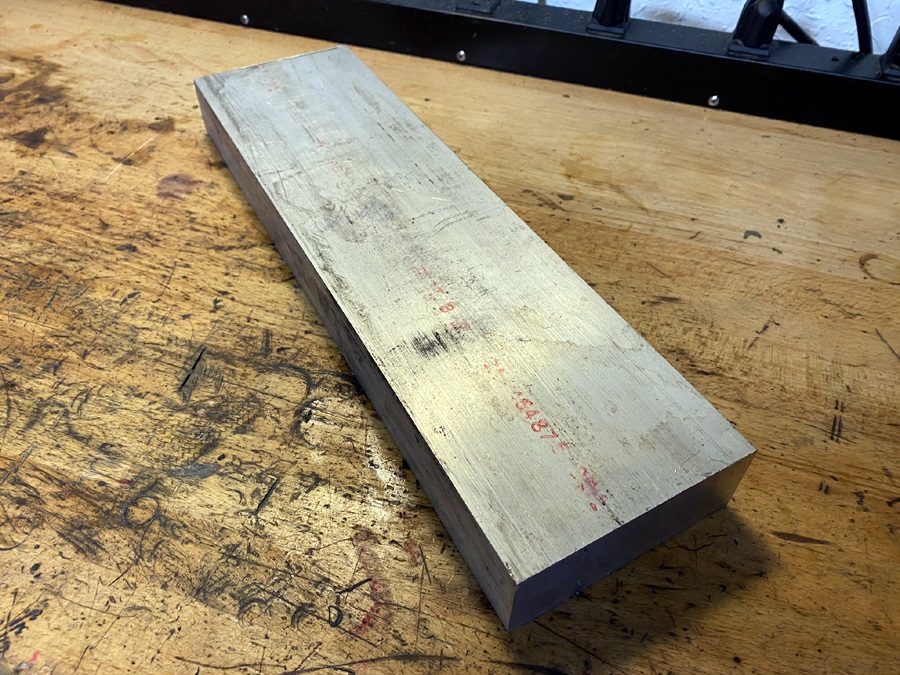

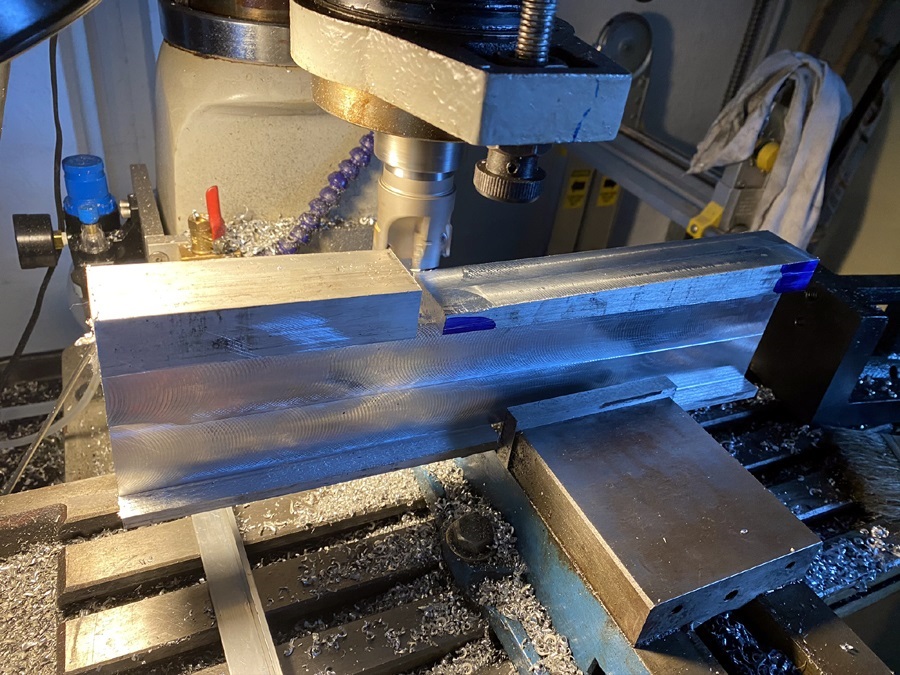

The “Fast & Furious” wing style had to go and the factory location just never seemed to look right to me. So a few hours of mill time gave this wing

a more symmetric stance by lowering and locating it rearward of the factory mounts. Billet was used because that’s what I had on hand, but it

made for a lot more time standing over the mill.

|

|

|

|

|

|

|

The most noticeable issue was the shifter; it was nearly impossible to locate the gates (right-and-left movement). The entire assembly was

removed, bead blasted, painted and a number of rebuild components ordered and installed. The new brass bushings, shims and cable made for

much better action.

One area that was particularly aggravating for me was locating a shift ball that would fit GM’s proprietary stick, so I machined a piece of steel

billet w/set screws and welded it in place of the factory stick. Now just about any aftermarket shift handle will fit the car and it’s adjustable as well.

|

|

|

|

With the shifter completely rebuilt it was onto the gate issue. Side-to-side movement was so difficult it was nearly impossible to locate the gates

(1st & 2nd, 3rd & 4th, 5th & R). It turns out that over time, heat from the header & crossover pipe had caused the cable lining to swell and pinch the

cable. Hanging here on the lift is the new select cable which is apparently made from gold-plated Chinesium--$113 a pop!

|

|

|

|

The console is back in tact with a purple knob on top.

She shifts like butter and looks good doing it!

|

|

|

|

After a few hours of scrubbing and shampooing the interior looks and smells much better

|

|

|

|

The rear custom built header routed so close to the distributor and coil it would periodically fry the module, so out it came for a little fab work.

The bottom of the crossover pipe was resting on the top of the distributor hold down bolt, so a few minutes with a torch and body hammer remedied that.

While massaging in the relief a nearby weld opened up requiring a bit of MIG and highspeed carbide cutter time.

|

|

|

|

A few minutes in the blast cabinet, two coats of VHT header paint, some 2” titanium exhaust header heat shield and back in the car.

Now much of the heat that was finding its way into the doghouse is being blown out the tailpipes!

|

|

|

|

A couple more “Father Time” issues were discovered with the other header, distributor and wires. After welding up the header it only made sense

to completely replace the 35-years old distributor and coil. Topping them off are a set of 8mm Splitfire™ wires and NGK plugs

|

|

|

|

The original coil, like the distributor was about one half of an inch from the exhaust crossover pipe, so I spent some time designing a heat shield for

isolation and fabbed up a new coil bracket to move it up closer to the deck lid. This bought about seven inches of additional separation and should

allow the coil to produce energy more efficiently.

|

|

|

|

Two of the ways to claw back power include greater air flow and cooler intake air temperatures. For every 10 degrees of intake air temp drop you

gain back 1% of total horsepower. Although unlikely to achieve any real ram air effects with our little side scoop we can make it breath a bit easier by

opening up the scoop area, filter and bridge. We can also lower turbulence by straightening out some of those abrupt bends in the factory system.

|

|

|

|

Just for good measure we'll replace the gas cap with a new one.

|

|

|

|

More to follow...

|