Who’da thunk it? That I’d ever own such a magnificent piece of American history!

This is a true Henry car—all steel, 1934 Five Window Coupe Deluxe.

This is a general photo section followed by more detailed areas of the build w/additional photos.

Part of the fun in reassembling an old car you haven’t seen assembled before is figuring out just where everything goes.

Receipts in hand for the new motor purchased in 1996 and the area under the intake still looked brand new. After pulling the heads, however, it was discovered the plugs had been removed for paint and never reinstalled. A sure recipe for corroded cylinder walls and a locked up motor.

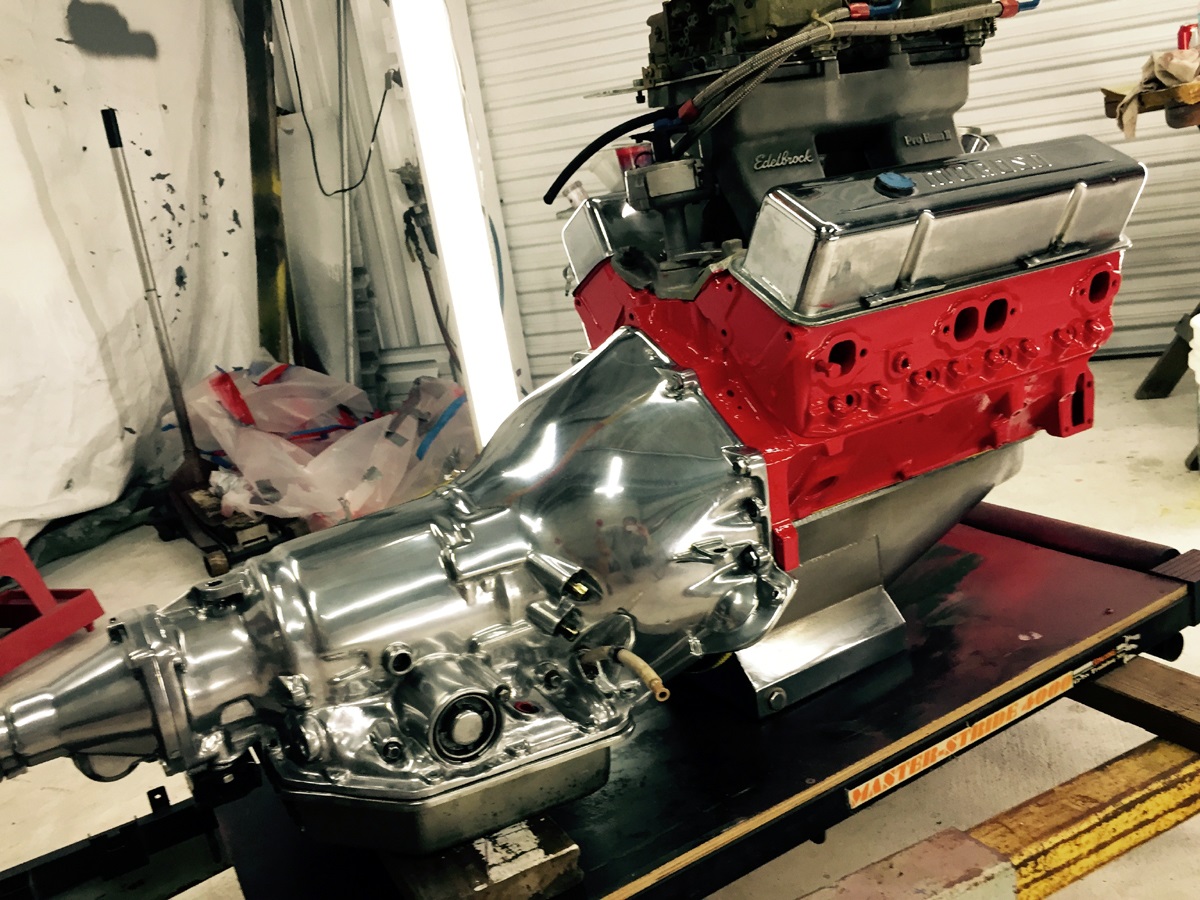

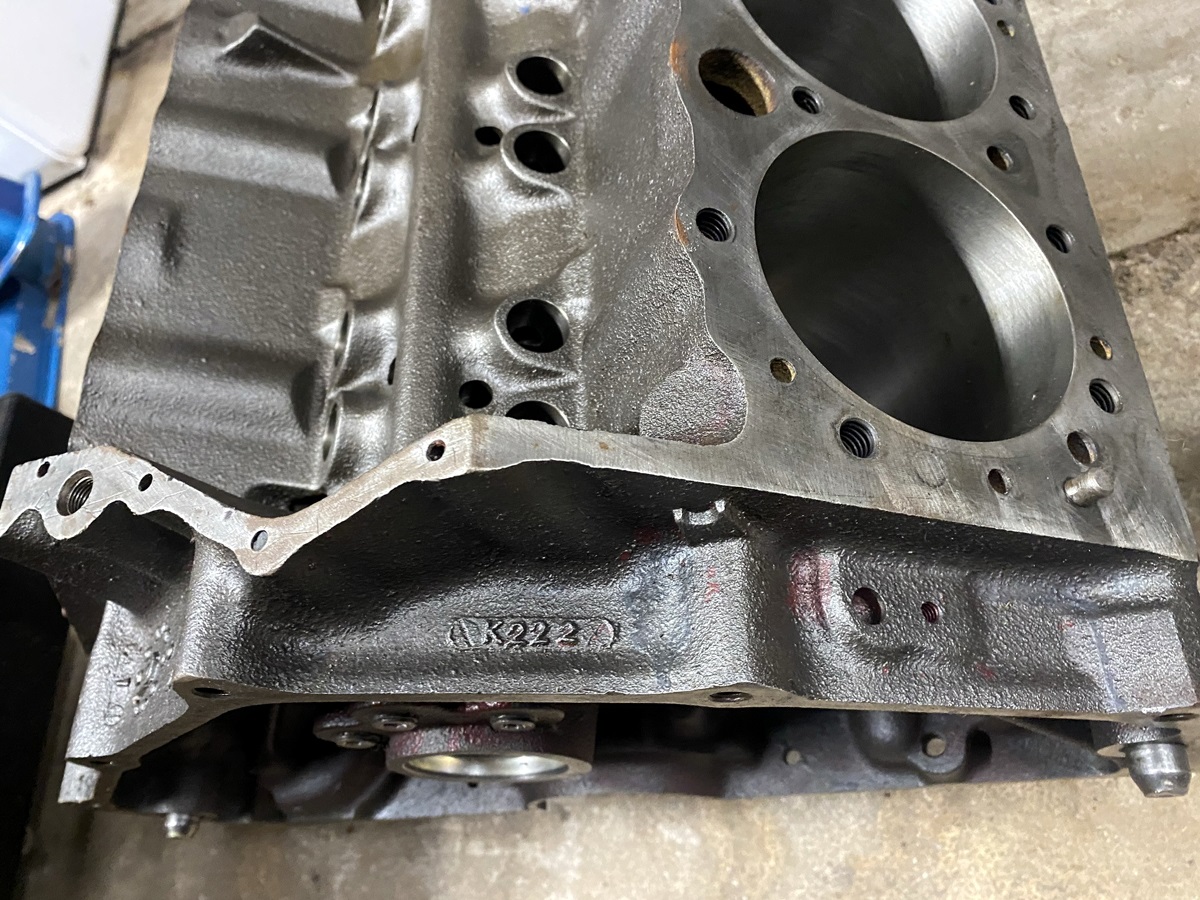

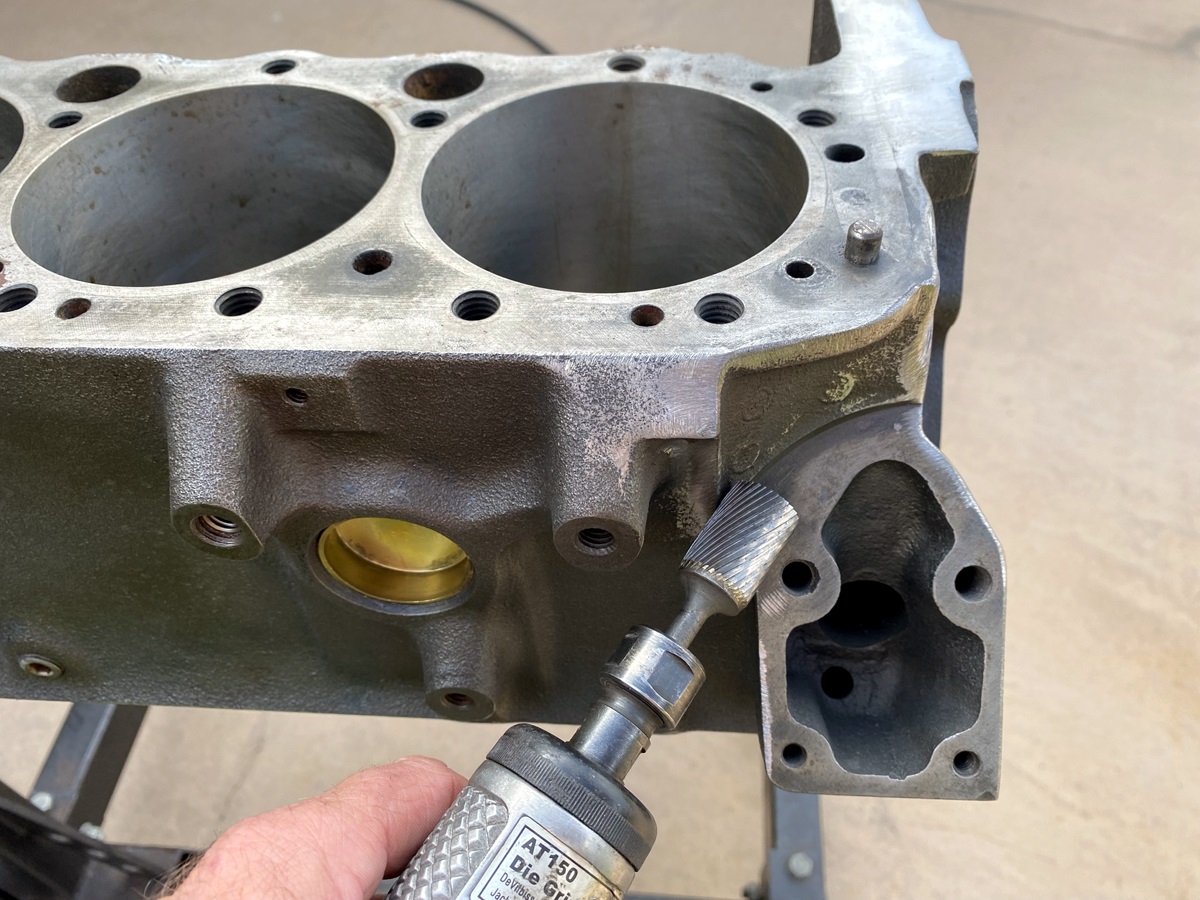

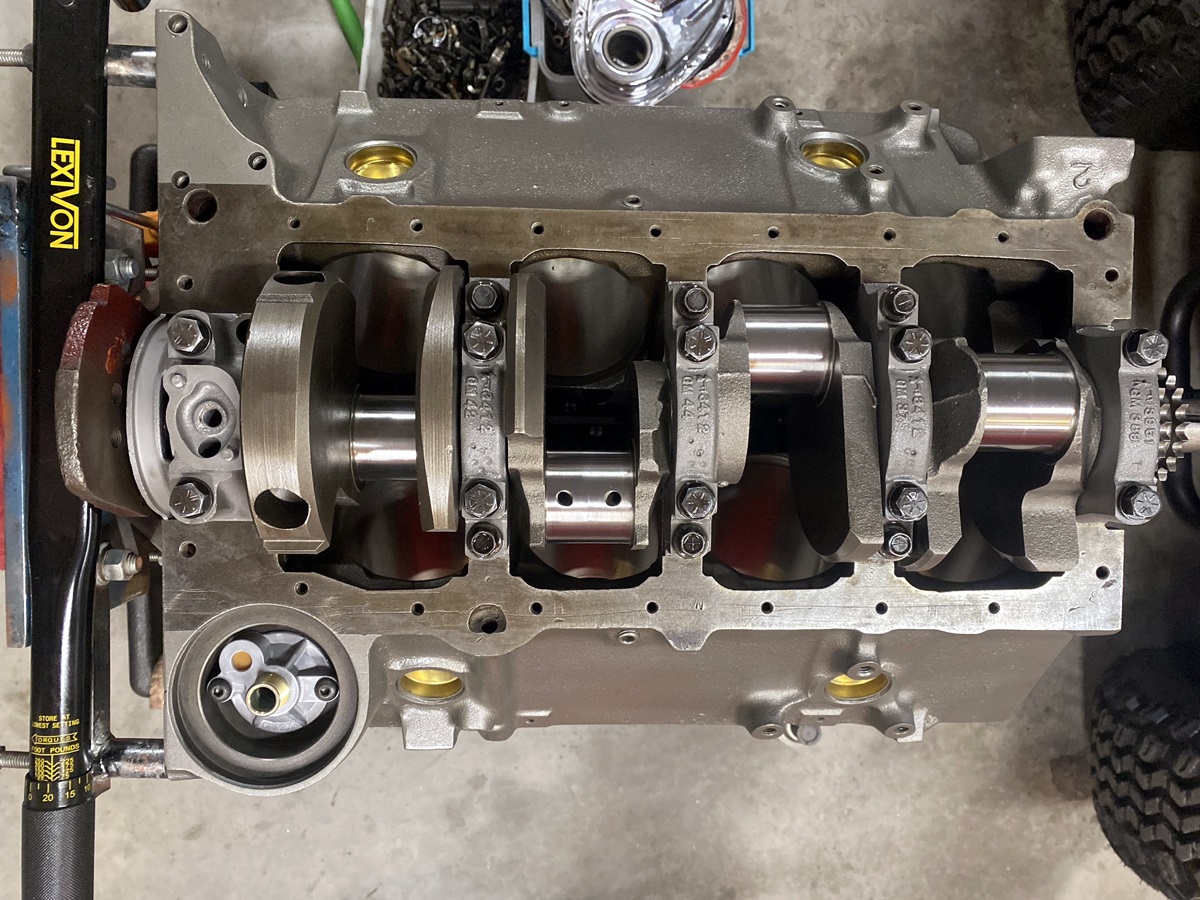

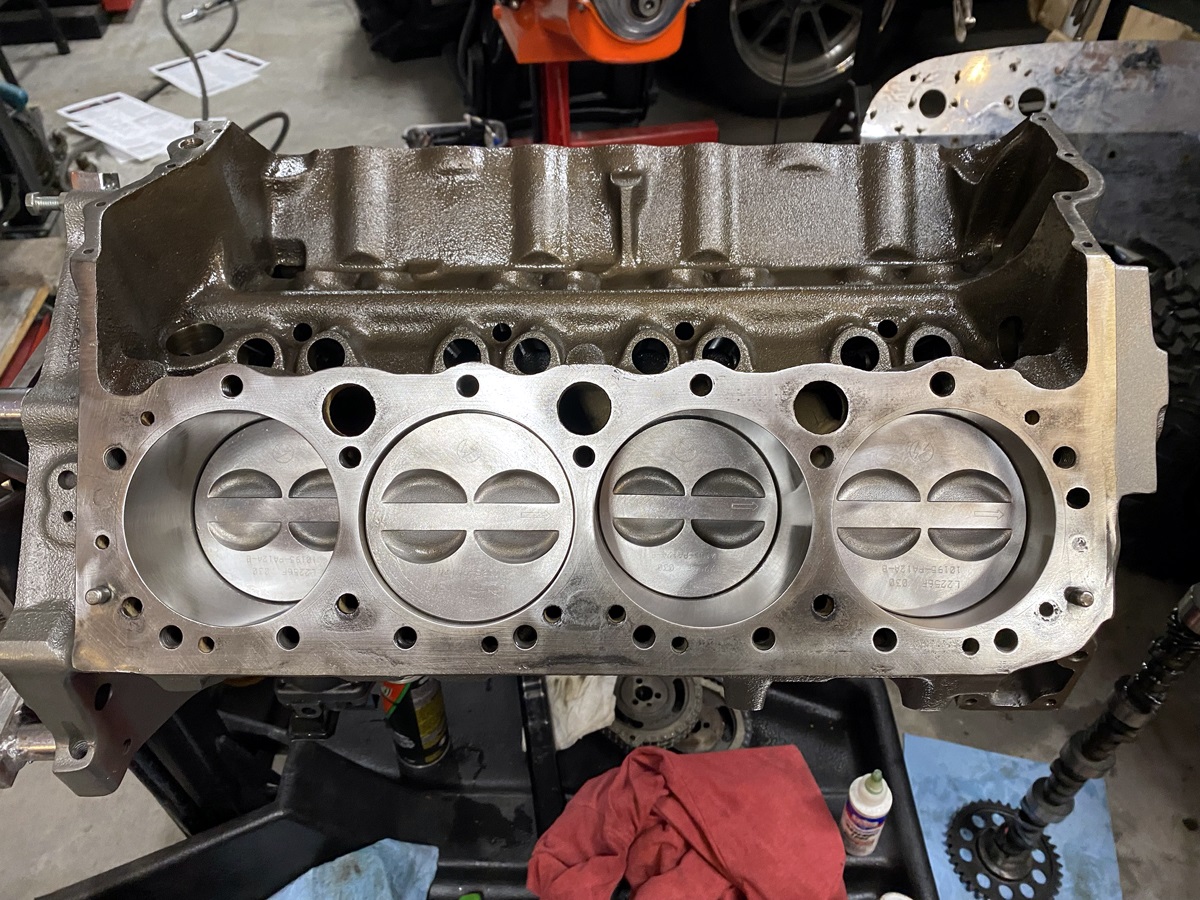

Fortunately, I keep spare, machined, blocks, rotating assemblies and master kits in the shop. After a couple hours of deburring, cleaning, blow drying, masking and spraying a fresh block is ready for assembly. I’ve been using Dupli-Color Engine Paints for many years and think theirs lays down well and is quite durable after a couple heat cycles. This motor gets their Ceramic Cast Coat Iron Enamel (DE1651).

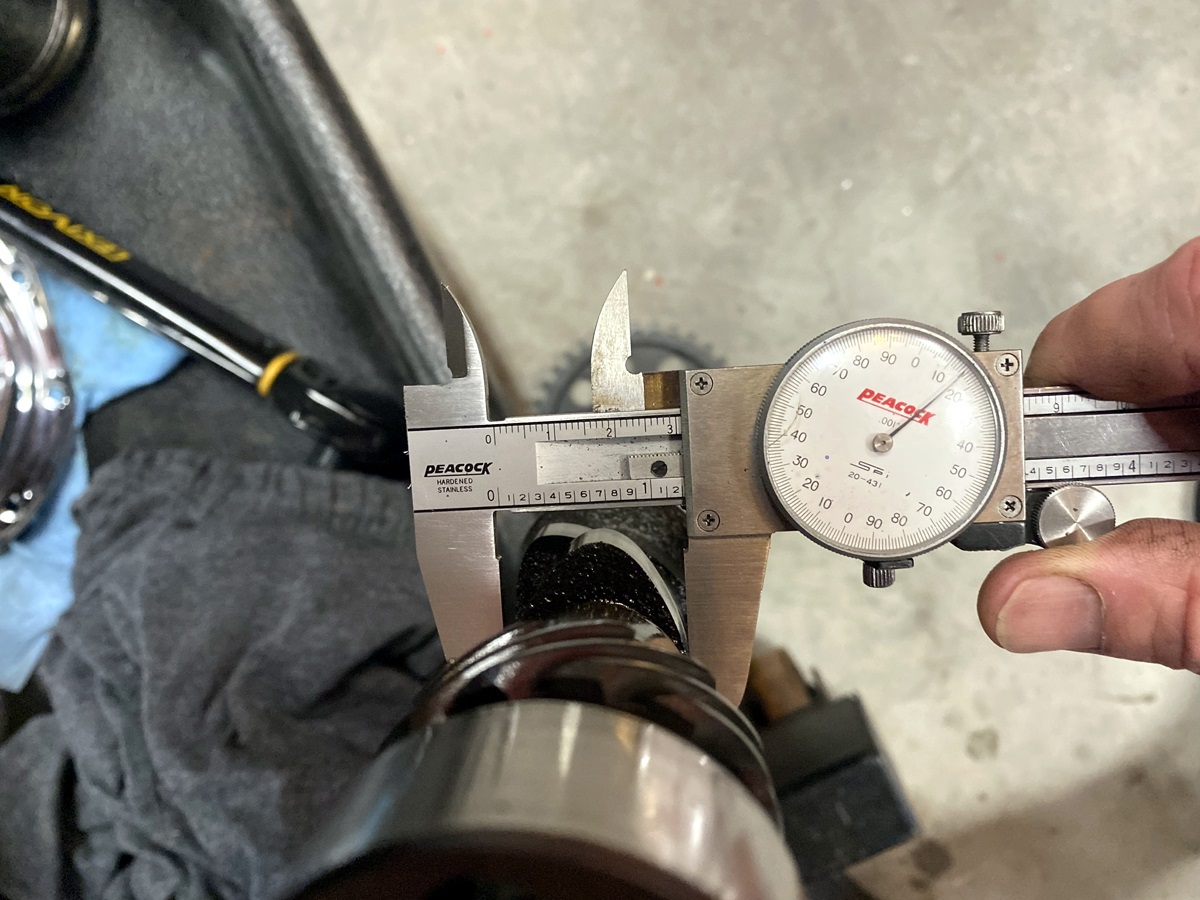

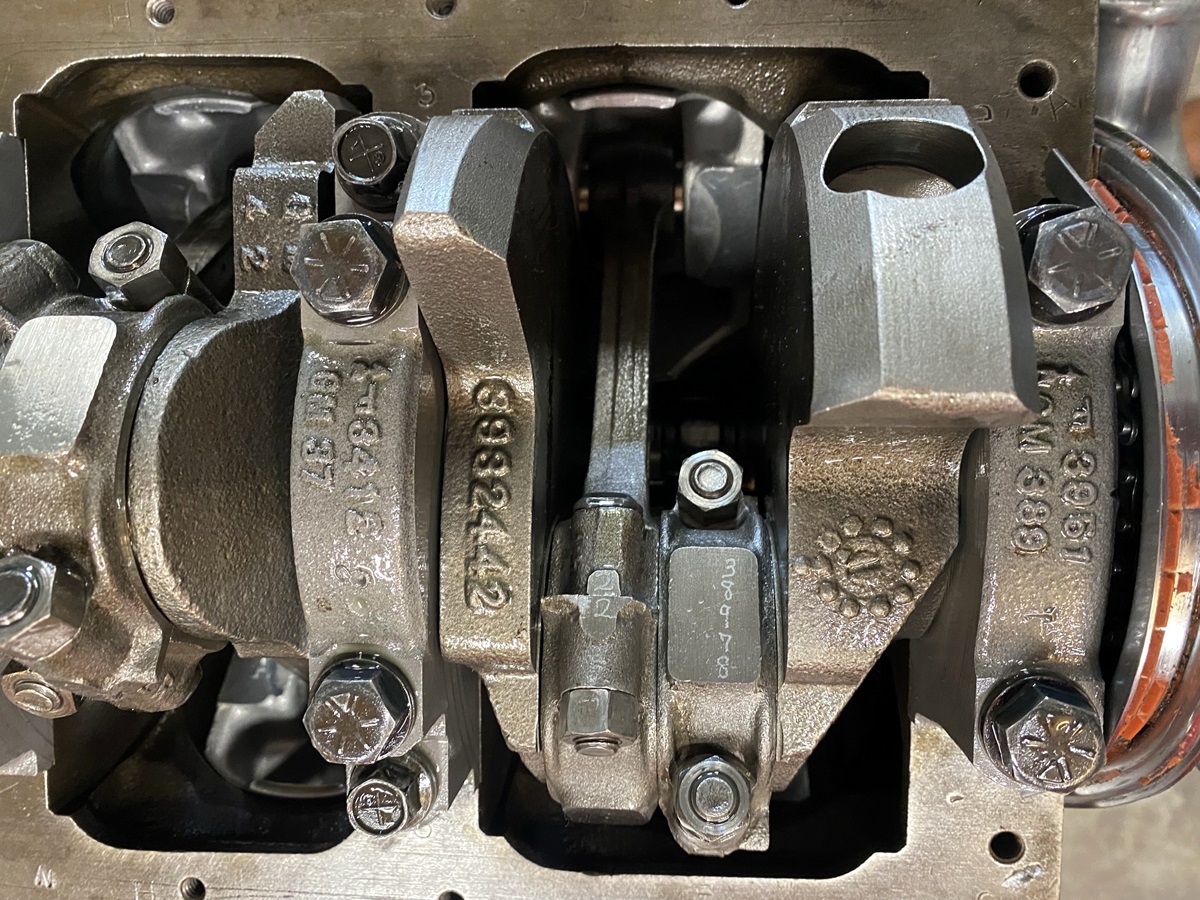

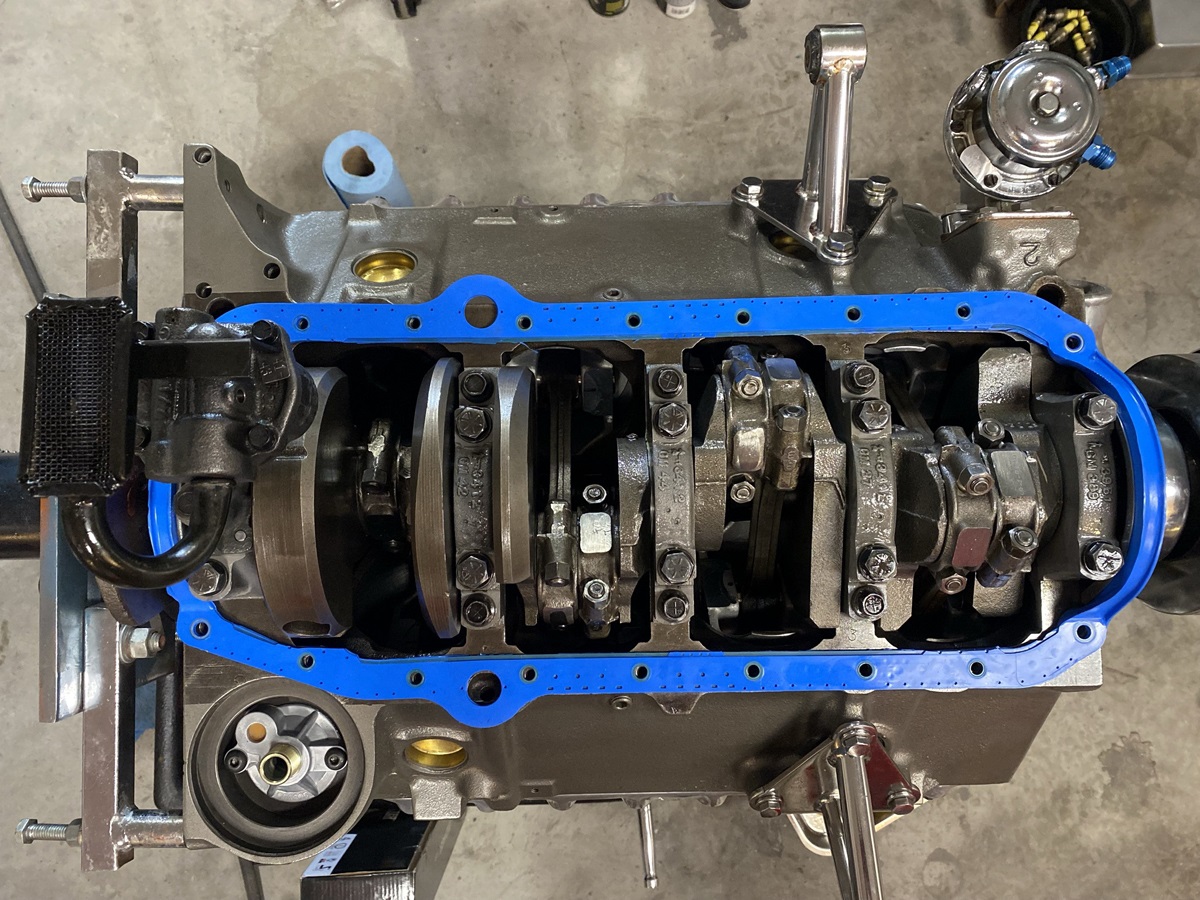

After blueprinting and bearing matching, in goes the crankshaft, rods, pistons, wrist pins and rings.

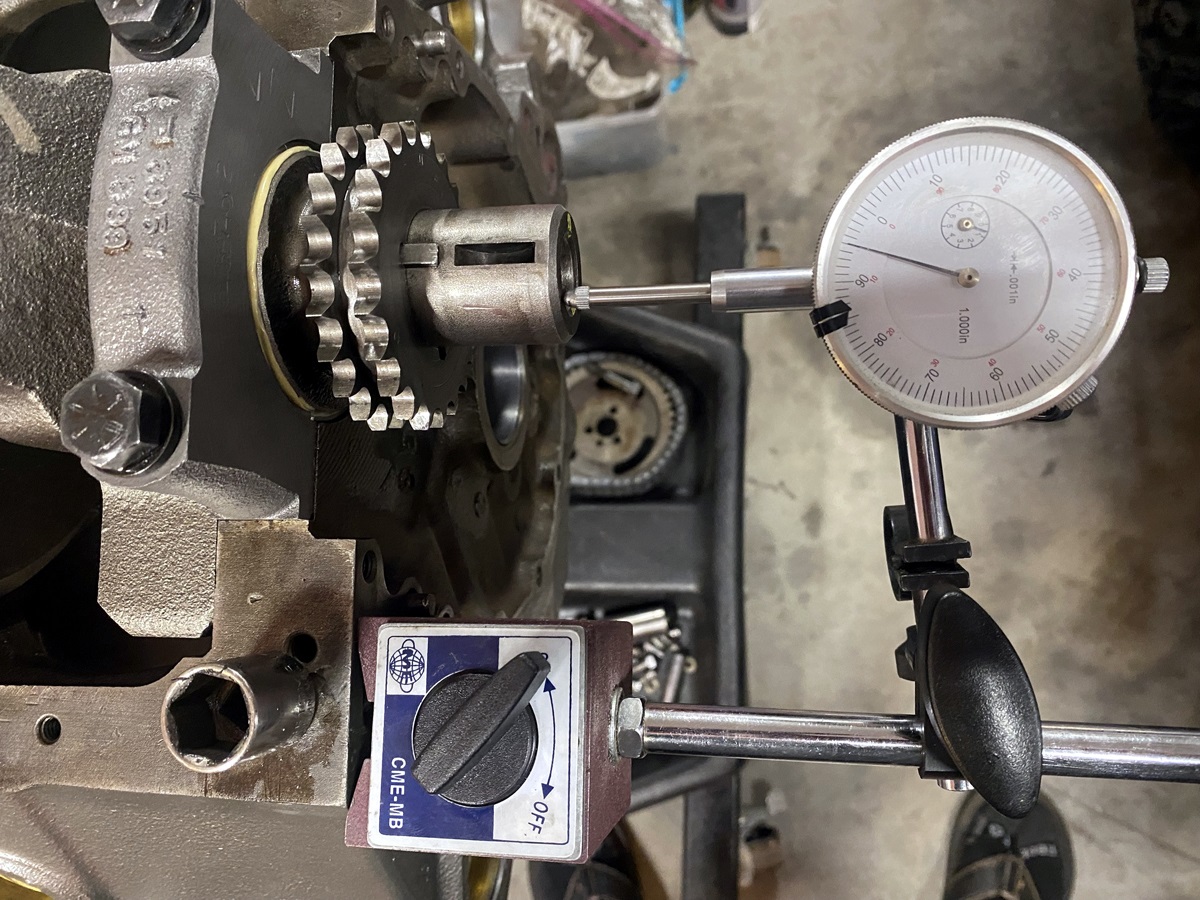

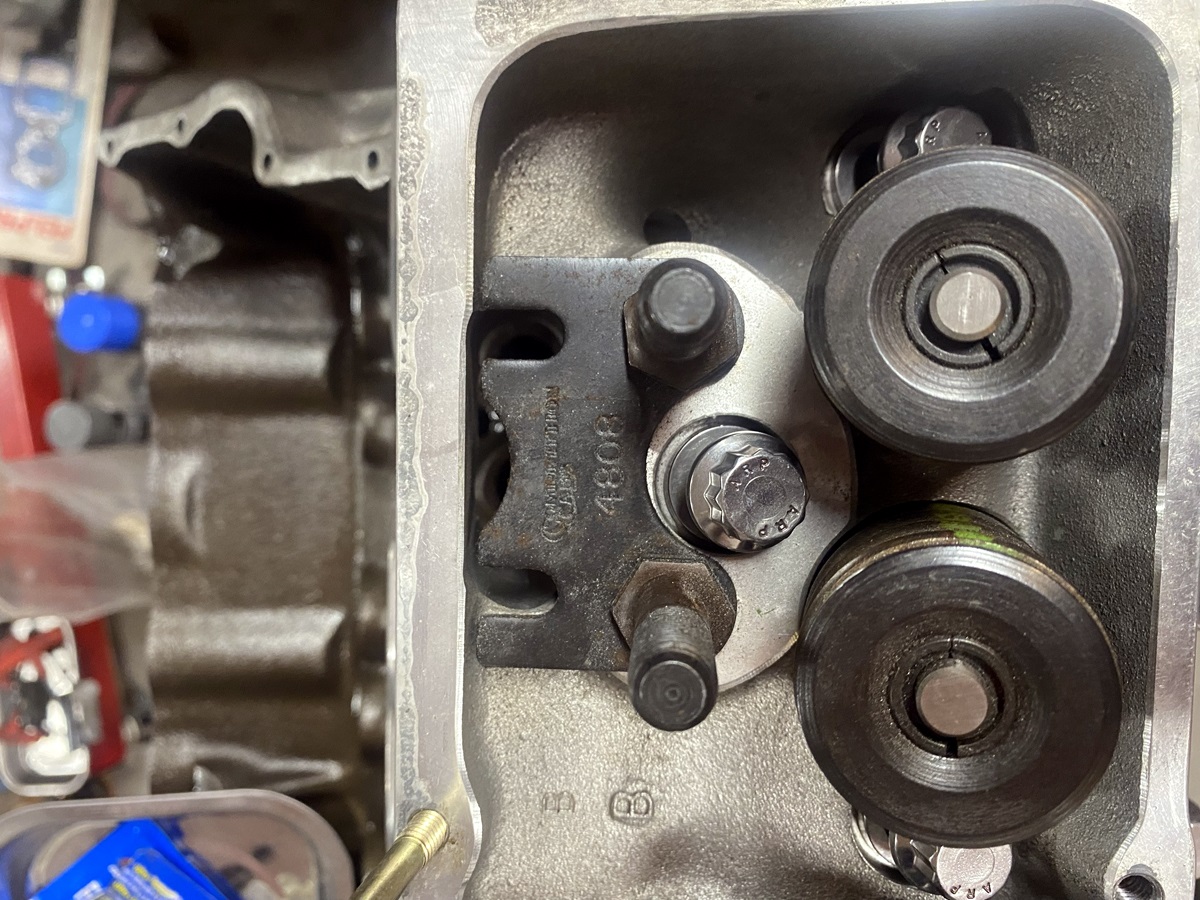

I reused the otherwise new cam and lifters, which is actually an Erson Blower Cam (472/.472 Lift x 220/228 Duration on a 112 Lobe Centerline). With the 1.6:1 Full Roller Stainless Steel Rocker Arms I purchased, it will churn out 503.467 lift which works for getting this car up and running under its own power as quickly as possible. I just don’t want to research, buy and break-in a new cam and lifters this week!

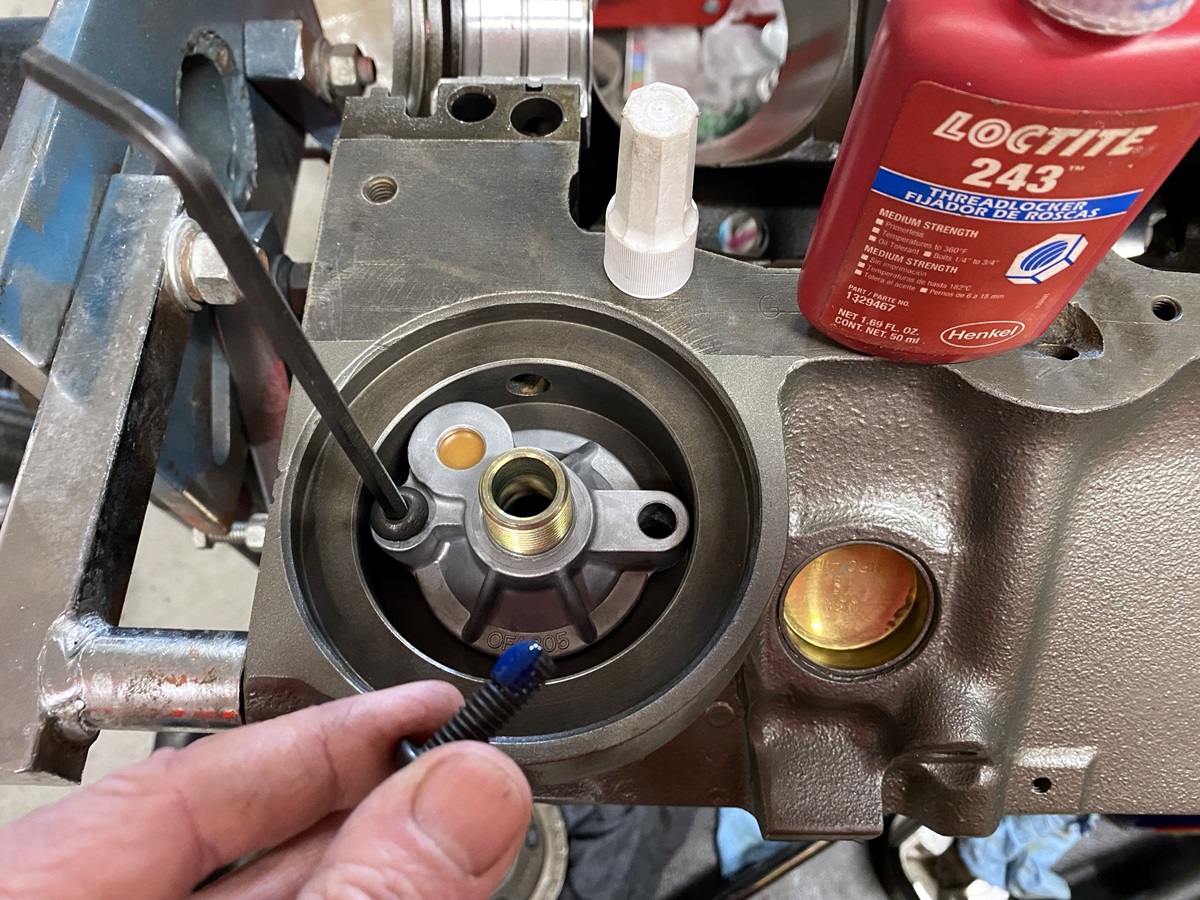

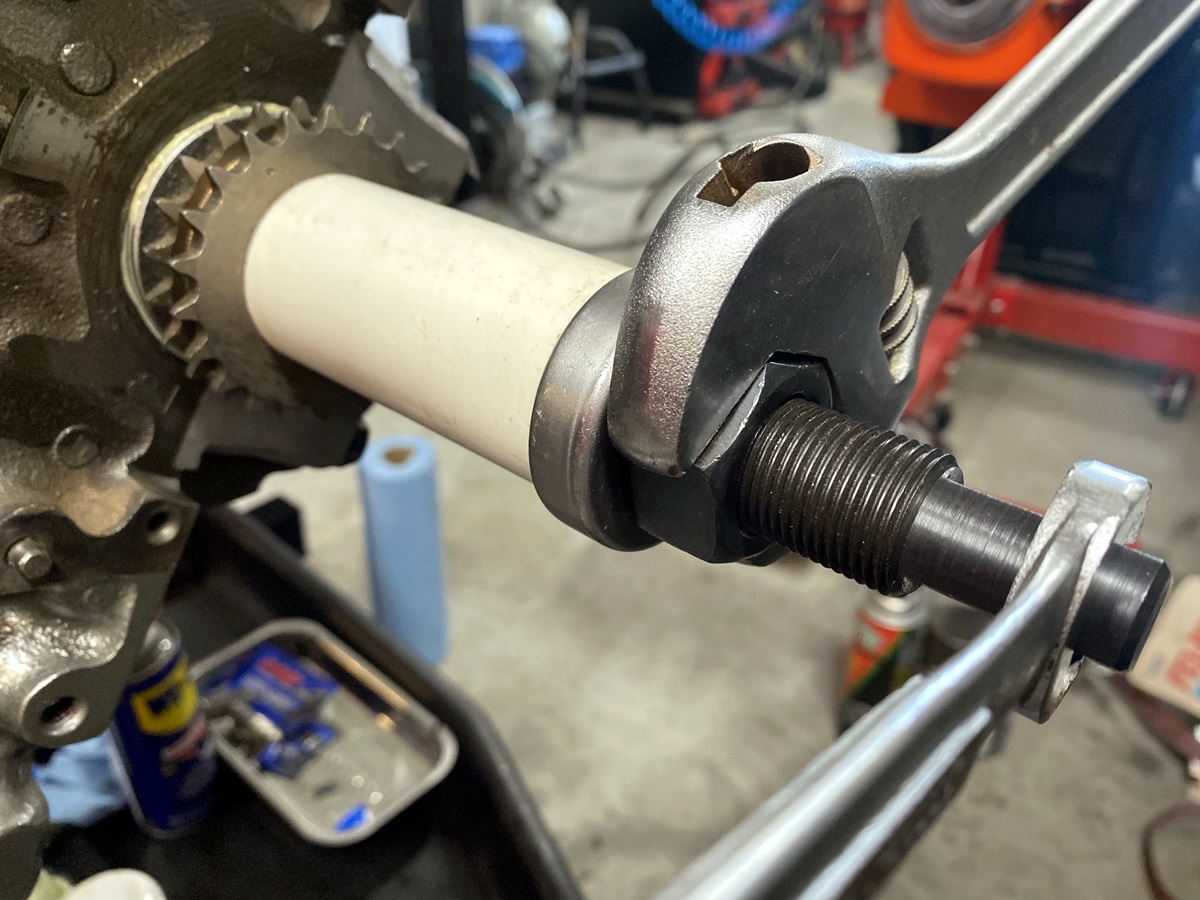

On with the Oil Pump Driveshaft, Pump and Pickup. No gasket used here, just machined surface to machined surface.

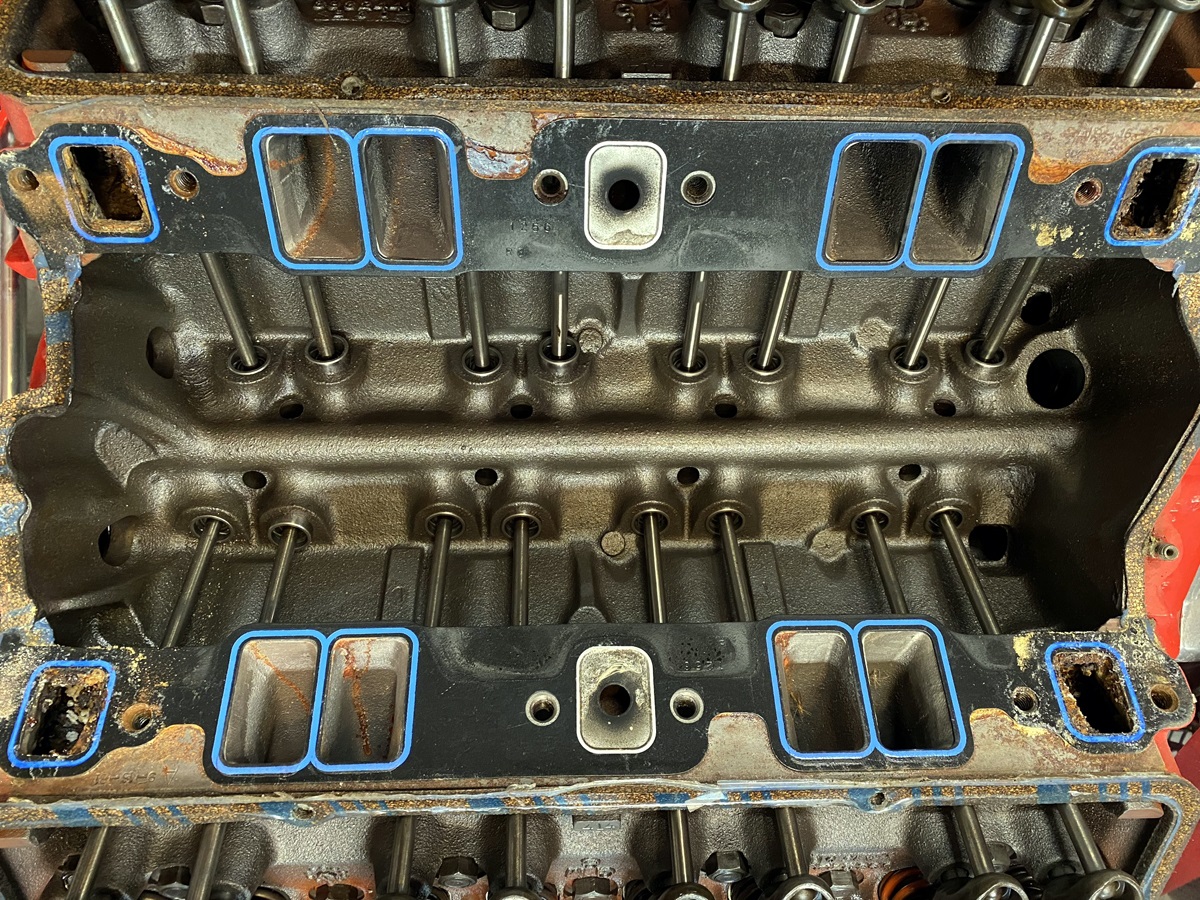

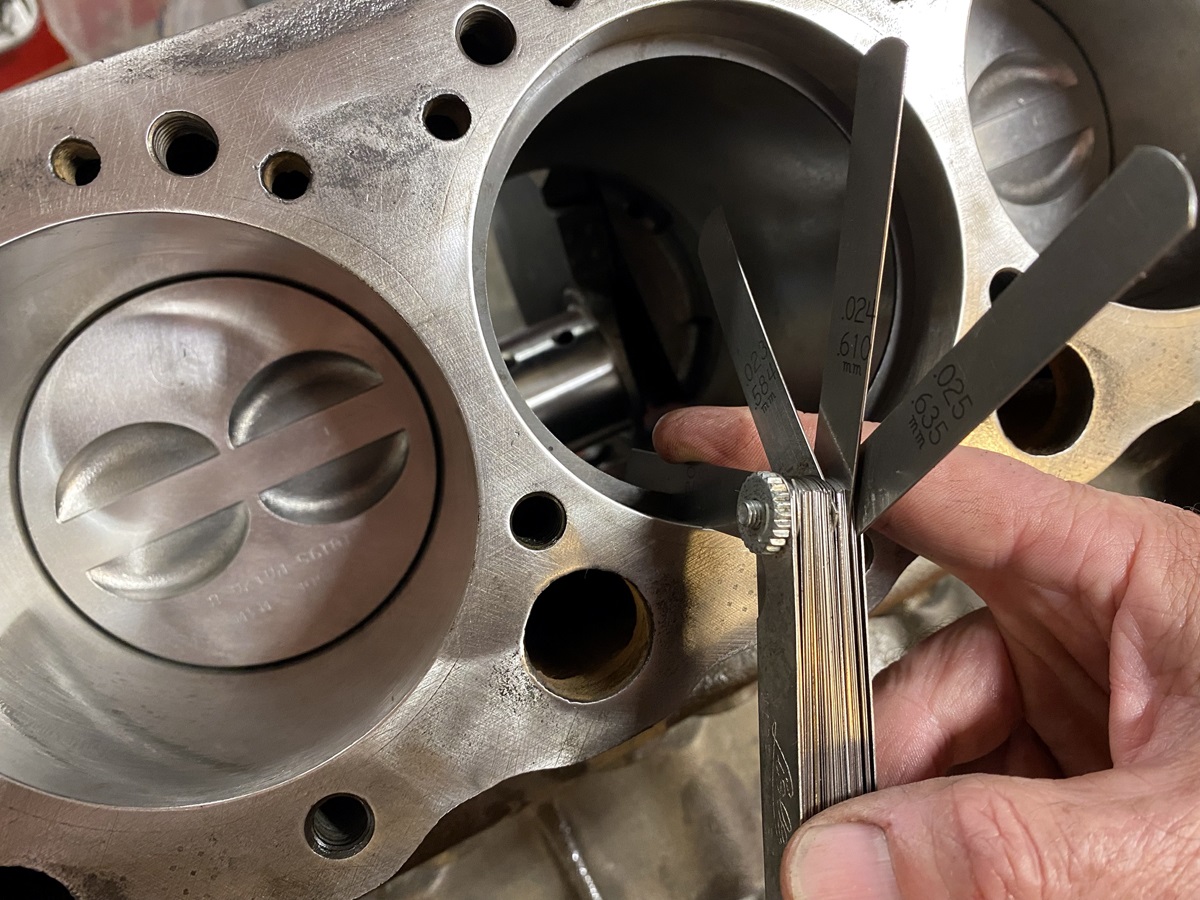

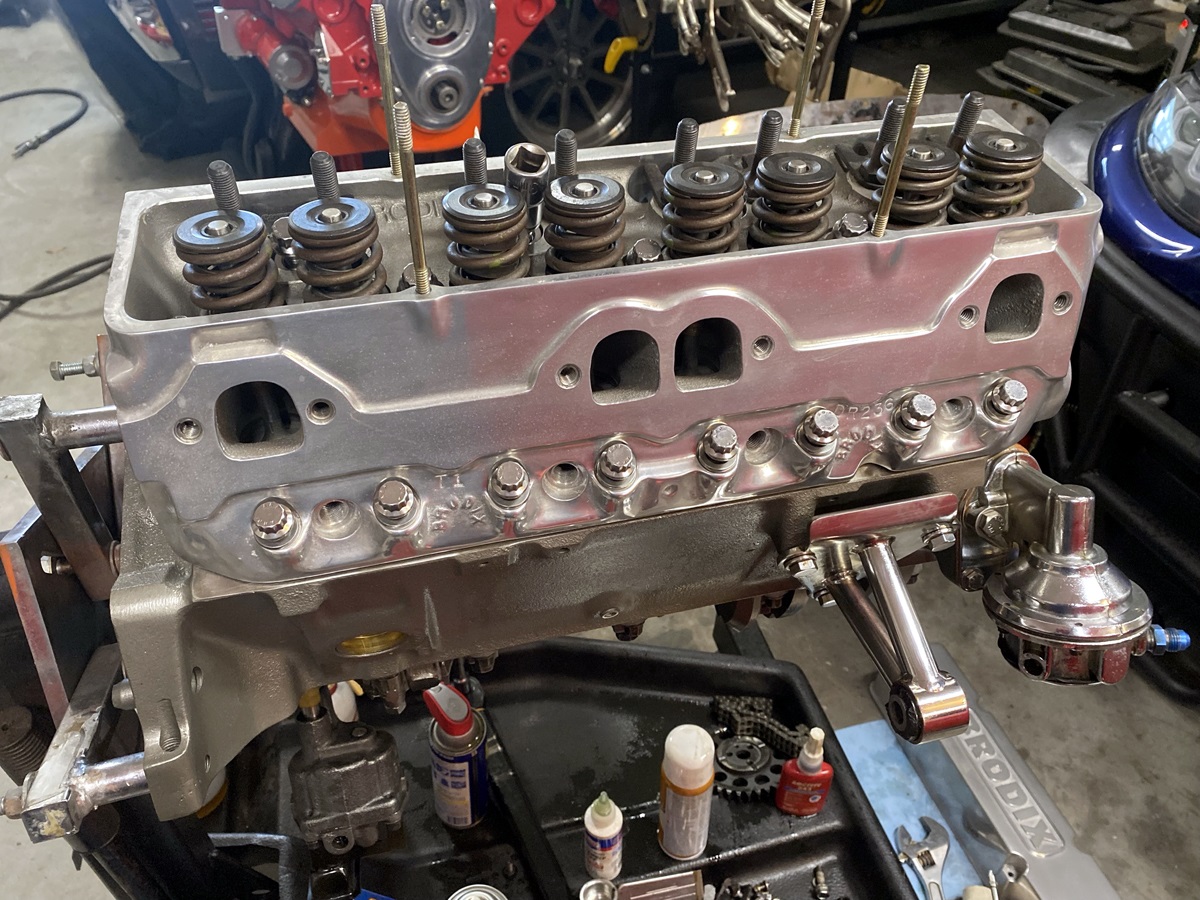

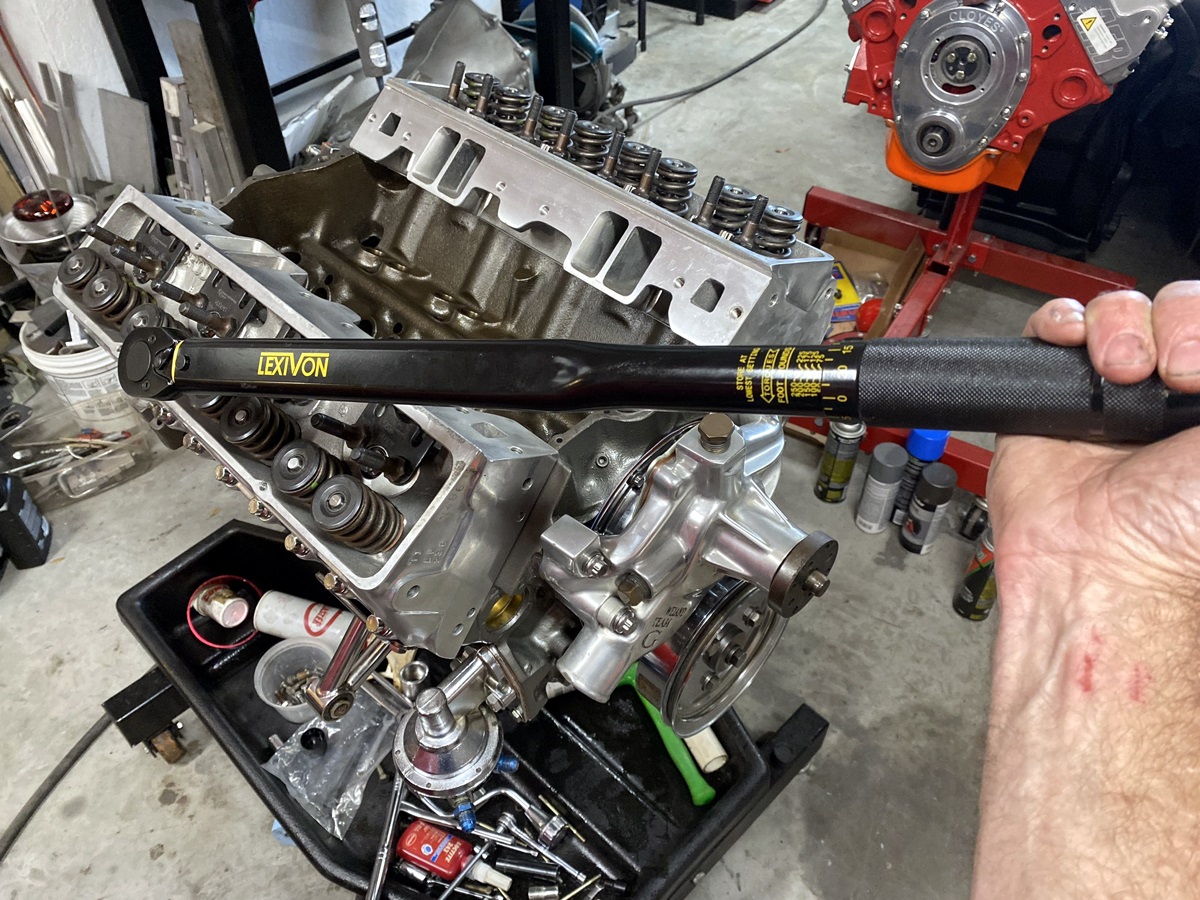

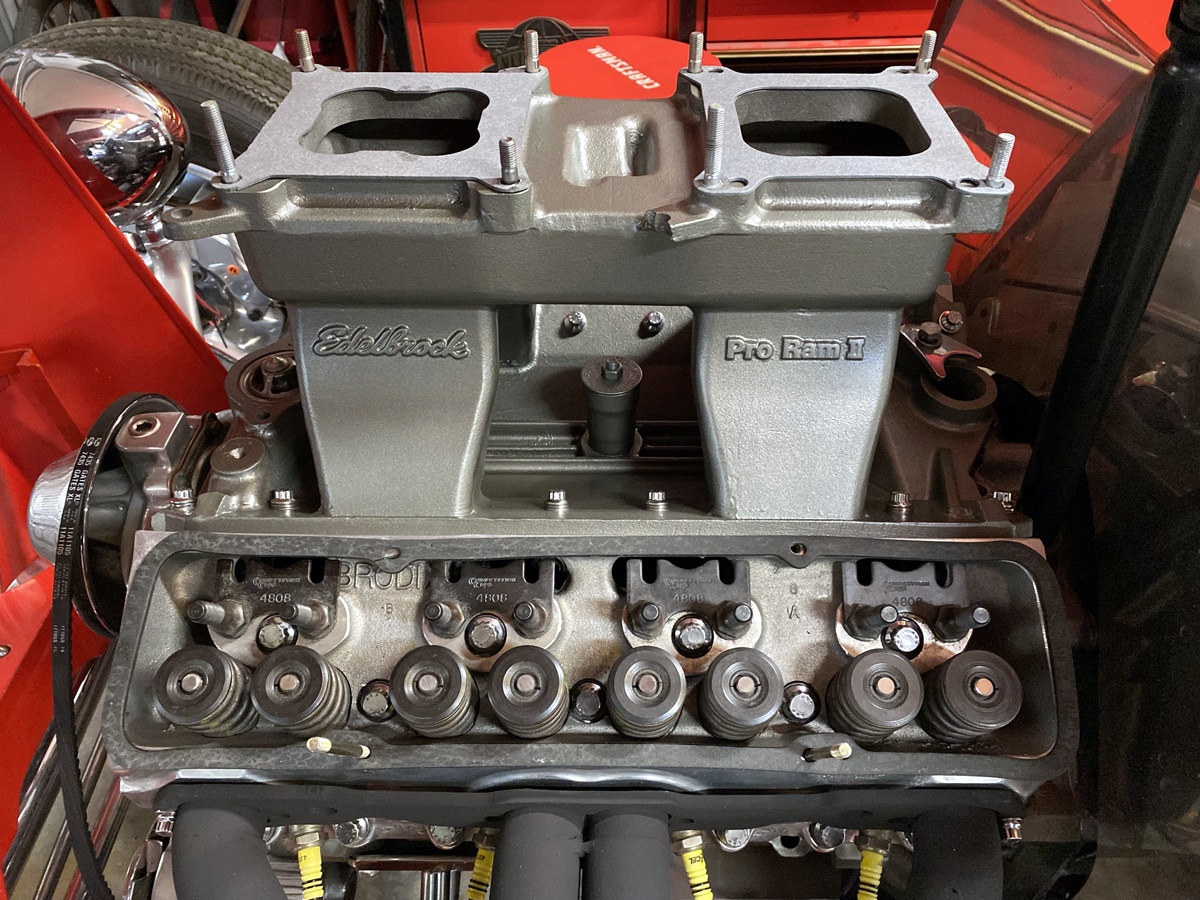

Next comes a beautiful set of Brodix Track 1’s with SS Valves, CNC Porting and 1.55” Double Valve Springs. Note the Polished SS ARP Fasteners—icing on the cake!

On with the water pump, harmonic balancer and some nice Brodix valve covers.

While waiting for the new Comp CAMS valve springs and tools to arrive I coke blasted, painted and installed the Tunnel Ram.

During the spring change process I found that Brodix--since they cater mostly to racing--does not install valve seals on the exhaust valves. Fortunately, I keep stock of these so on they went along with the new springs which are better fit for the Erson hydraulic flat tappet cam we're using.

After a lot of trial and error, returned parts and formation of additional vernacular I finally just repurposed the custom fender headers. Once blasted with coke they got a coating of VHT and will soon be wrapped in heat wrap before final installation.

The interior is a blank canvas and we’re just starting to paint it in. Note the Tilt Steering Column and new Steering Wheel assembly from Billet Specialties.

Once the suspension is dialed in and 3” Exhaust is plumbed, welded and hung we’ll lock down the fasteners and start installing the floor panels.

Those plastic rearview mirrors had to go! These billet pieces will look nice once I complete the fabrication and finishing work on their base mounts.